Categories

Categories

- Home

- Fiber Laser Machine

- FLASHLASER - SERIES

FLASHLASER - SERIES

sales@larosagroup.com

Product Description

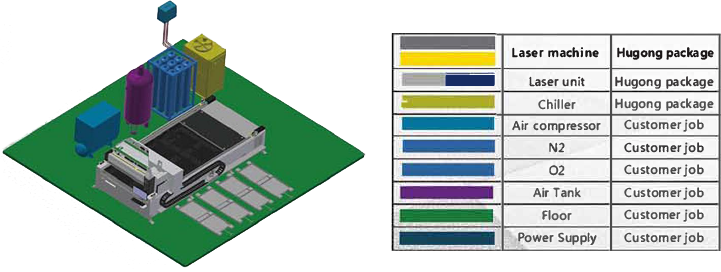

FLASHLASER

LASER CNC CUTTING MACHINE

| Machine key features and benefits | |

| Table structure | Structure is stress released after welding. Y rail is mounted on milled basement |

| Integral type gantry | Made by casting production. Ensure high precision and durability |

| Standard collecting drawer | Collecting drawer is configured to collect smaller parts and waste |

| Red pointer position | Red pointer is released for operator to check and confirm cutting torch position |

| Helical gear and track | To ensure high accuracy, high acceleration speed and long durability |

| Acceleration speed | Large capacity servo motor, high accuracy track and gear box to ensure 0.8G |

| Valve style gear box | Power is outputted by valve style gear. |

| CNC controller | 15'' monitor, with keyboard and mouse for easy operation |

| CNC controller disk | With 64G hard disk to ensure manage large projects |

| G code in software | Standard G code is configured |

| Cutting process model | Flying cutting mode, leapfrog cutting mode and normal cutting can be achieved |

| Centralized lubricator | Lubricator is regulated to lubricate by a timer |

| DXF/DWG input | LaserCAM nesting software supports to generate G codes |

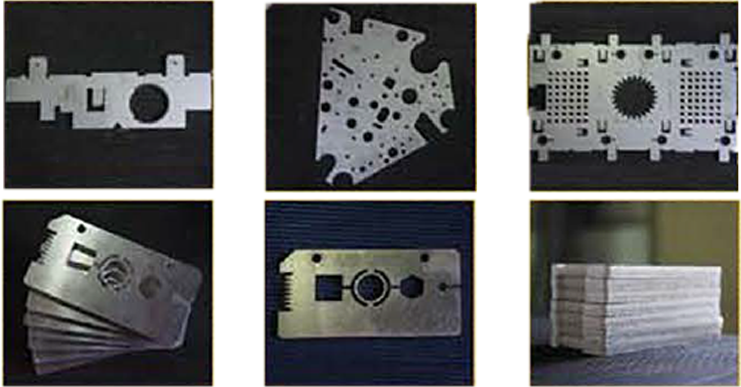

| Contribution to quality | Higher cutting quality will save cost |

| Contribution to efficiency | Higher cutting speed will improve production efficiency greatly |

| Key parts brand | |

| Laser generator | Raycus |

| CNC controller | Friendness with Cypcut software |

| Servo motor | Yaskawa,1.8KW and 1.3KW |

| Gear and Pinion | Sweden Linden and YCC |

| Cutting torch | Switzerland Raytools |

| Gear box | Taiwan Apex |

| Linear rail | Hiwin |

| Driving on X axis | Linear and gear |

Loading... Please wait...

Loading... Please wait...