Categories

Categories

Why should we replace Plasma Cutting Machine with Fiber Laser Cutting Machines?

Posted by on

Introduction:

Plasma cutting machines have been the industry standard for many years, but they are now being replaced by fiber laser cutting machines.

Fiber laser cutting machines offer a number of advantages over plasma cutting machines, including:

• Higher cutting speeds: Fiber laser cutting machines can cut materials at speeds up to 5 times faster than plasma cutting machines. This can significantly improve productivity and reduce production time.

• Higher quality cuts: Fiber laser cutting machines produce cleaner, smoother cuts with less heat-affected zone (HAZ). This can lead to less distortion and better surface finish.

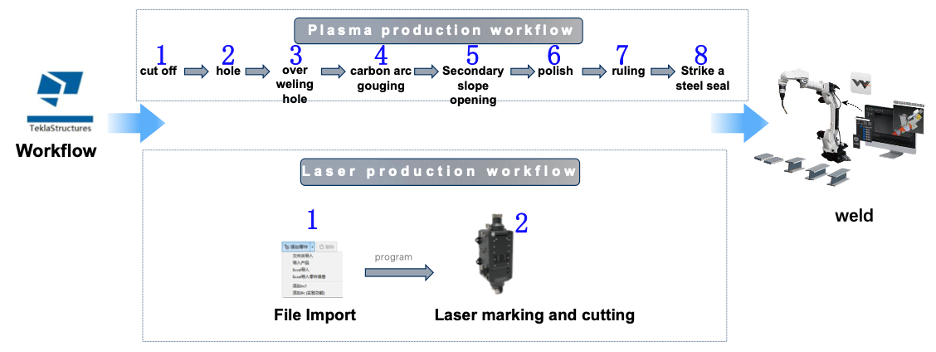

The process is reduced, and the production is simple.

Traditional plasma cutting requires 8 processes, while laser cutting only requires 2 processes, improving cutting efficiency.

• Greater material compatibility: Fiber laser cutting machines can cut a wider variety of materials than plasma cutting machines, including stainless steel, aluminum, and copper.

• Lower operating costs: Fiber laser cutting machines are more energy efficient and have lower maintenance costs than plasma cutting machines.

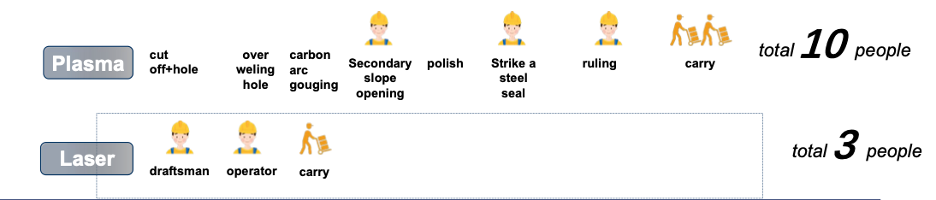

Reduce labor costs

Using a High-Pressure Screw Compressor:

1. Reduced Gas Consumption: By providing a consistent and high-pressure supply of assist gas (such as nitrogen or oxygen), the laser cutting process becomes more precise and efficient. This can lead to reduced gas consumption during the cutting process.

2. Optimized Cutting Performance: The increased pressure from the screw compressor ensures a steady and reliable flow of assist gas to the cutting head. This helps maintain optimal cutting conditions, resulting in higher quality cuts and minimizing the need for rework.

3. Flexibility in Gas Selection: High-pressure compressors can accommodate a wider range of assist gases, allowing for flexibility in choosing the most appropriate gas for specific cutting applications.

Cost-Benefit Analysis:

The cost of replacing a plasma cutting machine with a fiber laser cutting machine can vary depending on the size and complexity of the machine. However, the overall cost savings can be significant.

Here is an example of a cost-benefit analysis for a company that is considering replacing a plasma cutting machine with a fiber laser cutting machine:

| Expense | Plasma cutting machine | Fiber laser cutting machine |

| Purchase price | $20,000 | $50,000 |

| Annual operating costs | $10,000 | $5,000 |

| Increased productivity | 20% | 50% |

| Material savings | 10% | 15% |

| Total cost savings | $25,000 | $67,500 |

Payback period

The payback period for replacing a plasma cutting machine with a fiber laser cutting machine is typically between 1 and 2 years. This means that the company will recoup their investment in the new machine in just 1 or 2 years.

Conclusion

Replacing plasma cutting machines with fiber laser cutting machines is a smart investment that can significantly improve productivity, reduce costs, and improve the quality of products. Fiber laser cutting machines are the future of cutting technology, and now is the time to make the switch.

Case Studies

Here are a few case studies of companies that have successfully replaced their plasma cutting machines with fiber laser cutting machines:

• Company A: Company A was able to increase their productivity by 50% and reduce their costs by 20% after replacing their plasma cutting machines with fiber laser cutting machines.

• Company B: Company B was able to improve the quality of their products by 25% after replacing their plasma cutting machines with fiber laser cutting machines.

• Company C: Company C was able to recoup their investment in their new fiber laser cutting machines in just 18 months.

These case studies demonstrate the positive impact that replacing plasma cutting machines with fiber laser cutting machines can have on businesses.

Additional Benefits

In addition to the cost savings and productivity improvements, fiber laser cutting machines also offer a number of other benefits, including:

• Reduced noise: Fiber laser cutting machines are much quieter than plasma cutting machines.

• Improved safety: Fiber laser cutting machines pose a lower risk of fires and explosions than plasma cutting machines.

• Environmental benefits: Fiber laser cutting machines are more environmentally friendly than plasma cutting machines.

Conclusion

There are many reasons why companies should consider replacing their plasma cutting machines with fiber laser cutting machines. These machines offer a number of advantages over plasma cutting machines, including higher cutting speeds, higher quality cuts, greater material compatibility, and lower operating costs. The cost savings and productivity improvements that can be achieved by switching to fiber laser cutting machines can make it a wise investment for many businesses.

Loading... Please wait...

Loading... Please wait...