Categories

Categories

- Home

- Roll Forming Machines

- Door Shutter System

- 3 IN 1 DOOR SHUTTER SYSTEM- 3 IN 1 DOOR SHUTTER SYSTEM ROLL FORMING MACHINE-

3 IN 1 DOOR SHUTTER SYSTEM- 3 IN 1 DOOR SHUTTER SYSTEM ROLL FORMING MACHINE-

3 IN 1 DOOR SHUTTER SYSTEM- 3 IN 1 DOOR SHUTTER SYSTEM ROLL FORMING MACHINE-

Product Description

ROLL FORMING MACHINE

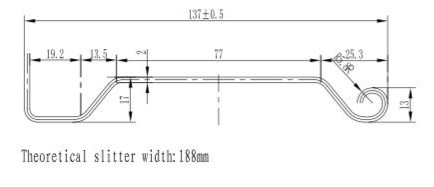

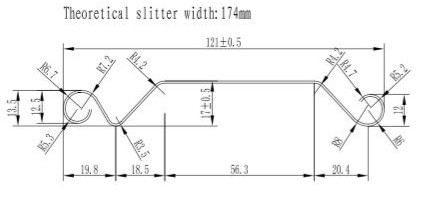

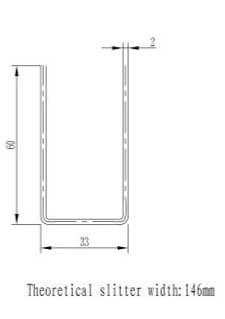

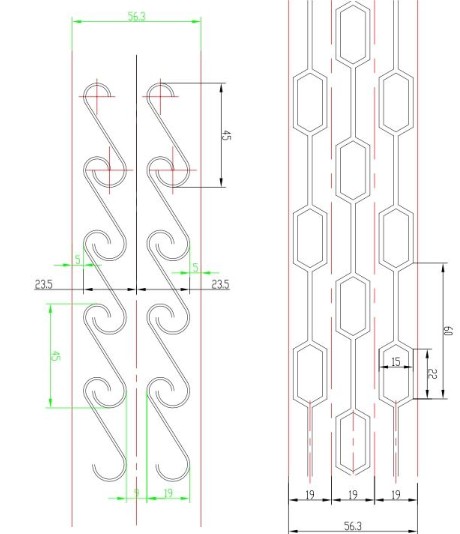

Work piece drawing:

Work piece sample:

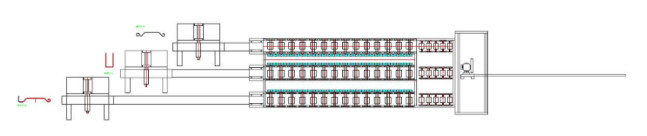

Machine Lay-out:

Technical Parameters:

|

Machine Name |

3 IN 1 DOOR SHUTTER SYSTEM |

|

Material parameter |

Material: G.I |

|

Thickness: Down side & U channel Profile: 1.2mm~2.0mm Door Shutter: 0.4 – 0.8 mm |

|

|

Input width: |

|

|

Work piece parameter |

1、Drawing ● |

|

2、Sample |

|

|

producing process |

Uncoil → roll forming → cut-off after sizing →final product |

|

Expand De-coiler (1 SET) |

Expand quomodo:Manual |

|

Inner diameter:450-520 |

|

|

Max. load capacity:1500KG |

|

|

Outer diamete:1200mm |

|

|

Max. width:300mm |

|

|

Roll forming machine (3 SETS) |

Forming steps:14 team |

|

Leveling steps:5 team |

|

|

Roller’s specification:GCr15 |

|

|

Quenching hardness:HRC58º-60º |

|

|

Bearing model:6308(2 SET)6208(1 SET) |

|

|

Roll shaft :45# |

|

|

Diameter:Φ48 |

|

|

Motor:7.5KW |

|

|

Reduction box:JZQ350 |

|

|

Roll forming speed:8-10M/min |

|

|

Saw cut-off system (1 SET) |

Cylinder:100×75 |

|

Material of the cut-off blade:Cr12MoV |

|

|

Quenching hardnes:HRC58~62º |

|

|

Cut-off blade(with burs):1 set |

|

|

Return quomodo:Cylinder |

|

|

Product run-out table |

Table lengths:4000mm |

|

Width:100mm |

Loading... Please wait...

Loading... Please wait...